History

Each year Dansand produces 380,000 tons of silica sand for four different business areas: industry & construction, sports & leisure, environmental protection and the do-it-yourself market.

We are present in almost 3000 DIY stores across Europe, and about half of the turnover derives from export to a number of local markets – including Germany, the Netherlands, Belgium, Norway, Sweden and the UK.

We are about 40 employees in production, product development, sales and administration.

Dansand A / S is owned by PKB Holding (50%) and Belgian Sibelco (50%), the world’s largest supplier of minerals.

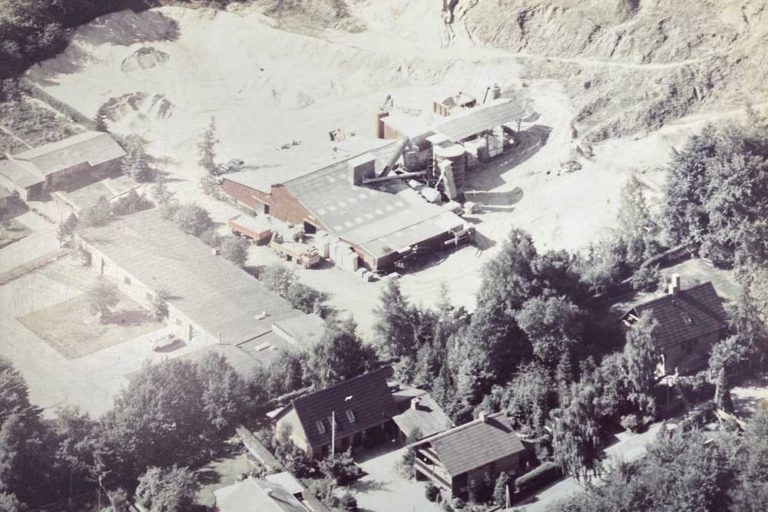

Poul Erik Beck founds Silbeko, later Silkeborg Kvartssand A / S. Since the beginning of the 60's, Poul Erik Beck has overseen the family business and haulage business Jens Konrad. The company owns several gravel pits, including the pit in Addit, which contains a unique reserve of "white" sand. The sand is of such a high quality that it can be used as an ingredient in industry. But sand is not just sand. Different customers and different industries place different demands on the composition of the material, and Poul Erik Beck sees potential in creating a new type of silica sand-based products. The idea is to separate the raw sand, wash and dry it and put together the special sand fractions that the industry demands.

In collaboration with the Danish Technological Institute and a small group of employees, Poul Erik Beck is working intensively to develop a product range that meets the specifications of the Danish foundry industry.

The company becomes the leading supplier of silica sand to the Danish foundry industry. The development work has created a knowledge base that makes it possible to live up to the foundries' very specific quality requirements. The collaboration with the foundry industry also opens the doors to several other markets such as the concrete and mortar industry.

Silkeborg Kvartssand gets its first order for top dressing for a Danish golf club. Up through the 80s, the company begins collaborating with more and more golf clubs who see the value in nurturing their courses with a quality sand product.

At the same time, the business area is expanded to also include the supply of silica sand-based products for football clubs, riding arenas, playgrounds and leisure institutions.

Silkeborg Kvartssand A / S changes its name to Dansand A / S. The same year, the company buys Lund Kvartsværk, including the plant's production facilities and bagging machines. The purchase makes it possible to deliver sand in bags directly from our own factory.

The daily operation of the company is handed over to new CEO Victor Jensen. Poul Erik Beck continues in his role as chairman of Dansand’s board of directors.

Dansand sells 50% of its shares to S. C. R. Sibelco Group, which is the world's largest supplier quartz of minerals.

Dansand acquires Søby Værk.

Poul Erik Beck's son, Poul Konrad Beck, takes over the management of Dansand. The Board of Directors and the new Executive Board are initiating a radical modernization of the company. All processes that can be automated are automated, and over the next 15 years, Dansand will invest massively in the latest production technology on the market.

Dansand acquires Weber Saint-Gobain's sand production in Silkeborg (at the time Optiroc). The plant is operated locally in Silkeborg until the following year, when all local production units are transferred to the headquarter in Addit.

Production and administration are gathered in the newly built domicile in Addit. We have built a new factory with some of the market's most advanced production equipment, including robot-operated packaging lines and digitally controlled washing plants and drying ovens, which employees can operate from home. We can now produce 24/7 without the employees having to go to work at odd times of the day.

Dansand buys Weber's sand production in Silkeborg (Optiroc)

Joint filling sand products

Dansand launches the first joint filling sand products for the DIY and retail market. Initially, the products will be sold on the Danish market.

Dansand buys Grejsdalen's Filterworks in Vejle

Dansand acquires DanGrit's sand production in Varde.

The financial crisis is raging, but the DIY products are now sold in DIY stores in Germany, Norway, the Netherlands, Belgium, and the United Kingdom. Despite the crisis, we are expanding the organization and creating an independent department for the DIY area with sales, complaint handling and marketing. So far, we have sold the products via distributors, but we want to put our own imprint on the market, partly by negotiating directly with the retail chains, partly by strengthening the DANSAND brand in the consumer segment.

We inaugurate our first fully automatic reading system. Here, mortar and concrete customers can pick up sand 24 hours a day without the involvement of Dansand's employees. It increases both our delivery capacity and gives drivers increased flexibility because they can pick up orders outside normal business hours.

Poul Konrad Beck resigns as CEO of Dansand. Instead, he takes over the chairmanship of Dansand's board from Poul Erik Beck, who passes the baton on to the next generation. Thomas Steen Hansen becomes CEO of Dansand.

Dansand buys Tandskov Gravel Pit. There is a growing awareness in society that silica sand is a limited resource. Dansand wants to ensure that the silica sand deposit in the gravel pit is optimally utilized and is not used for purposes where a more common type of sand could have been used.

Dansand celebrates its 50th anniversary. Over the course of 50 years, the company has evolved from operating a traditional sand gravel to being a specialized raw material company. Today, a third of Dansand's turnover derive from exports of highly processed products. However, these products make up only about 16 % of the quantities produced at Dansand. In 1971 Dansand’s most important asset was the white quartz sand, today it is the technical knowledge that is added to the products. The old formula, material + knowledge = value, is as relevant as it was in the early 70s.