Stone dust for narrow and broad joints

Additional information

| Responsible: | |

|---|---|

| E-mail: | |

| Producer: | |

| Product designation: | Crushed, washed and kiln-dried stone dust with added minerals |

| Tel: | |

| Item number: | |

| Variants: | Crushed, washed and oven-dried granite with added minerals |

Description

Our dark granite stone dust is a strong choice for both wide and narrow joints between concrete tiles and natural paving stones. The dust gives a fine result to match paving stones with particular characteristics such as cobblestones – and leaves very little dust.

The NO GROW mixture consists of crushed, washed and dried granite with an added mineral additive. The additive has a naturally high pH value, which creates a nutrient-poor growth environment in the joints. Weed seeds dry out and can not take root and germinate. The minerals dissolve slowly and are not washed out until after 10 years of rain. With the correct use of DANSAND® stone dust, you get a great result that lasts for many years.

BENEFITS OF Dansand® stone dust

- Crushed, washed and oven-dried granite with added minerals

- Dusty

- Naturally high pH value creates a nutrient-poor growth environment in the joints.

- Water permeable

- Easy to sweep into the joints

- Provides stable, compact joints – packs extra well in the joints.

- For wide joints up to 20 mm

- Effective at a joint height of minimum 40 mm

Specifications

Declaration

Dansand® stone dust consists of washed, oven-dried granite stone dust. A high pH mineral additive has been added. Available in anthracite. The joint material is ready-mixed and can be used directly from the bag.

Packaging

Frost-proof foil. Plastic bags made of PP material.

Storage

The bags can be stored outdoors during the summer. However, we recommend a covered storage location, as the plastic foil cannot tolerate heavy rain.

Safety

Safety data sheets can be obtained at the following link.

Delivery

20 kg in frost-resistant foil bag.

Environmental information and disposal

The joint material must not be classified as hazardous according to the Danish Ministry of the Environment’s rules for classification and labelling. Residues are handed in at the recycling station. The joint material must not be poured into the sewer. The plastic bags are made of PP material. Place in a container for combustible waste or for recycling.

The authorities’ requirements for the establishment, maintenance and grouting of fortified areas may vary nationally and locally. Therefore, familiarise yourself with the applicable national and / or local regulations before starting the joint work.

| Grain size | 0-3 mm |

|---|

Manual

Application

For new and existing paving. Only for outdoor use on dry foundation. Only suitable for unbound substrate. Suitable for private use.

Estimated amount: At 14x 21×5 cm paving stones with a joint width of 2–3 mm = 2.0 kg/m2 . Our coverage calculator can help you find the correct amount you need.

Joint depth must be 40 mm minimum. Joint width must be from 3 to 10 mm.

How to do it

The paving stones are laid on a sustainable gravel and sand layer in accordance with current standards for paving work. The joint material is water-permeable like ordinary jointing sand, which is why the base layer must also be water-permeable.

Refilling

DANSAND® Stone dust is not a remedy for weeds. To prevent existing weeds from growing, weeds and roots must be completely removed before filling the joint. Clean the joint of old joint material to a depth corresponding to the entire height of the stone. This is done with a joint cleaner. Next, you can use a high-pressure cleaner, but be careful not to damage the paving stones or the substrate. Refill the joint as described during grouting of new paving.

Maintenance

To avoid weeds in the joints and displacements in the coating, the joint must always be filled to the full height and be completely free of soil and other organic material. The paving can be cleaned with a stiff broom as needed and the joints refilled. Moss and algae can be removed by suitable means. Extreme weather conditions can cause efflorescence in the joints and on the edges of the paving stones. However, this is usually washed off at the next rain shower. You can also remove these salt deposits by regular cleaning of the paving stones.

Please note:

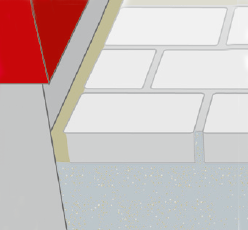

- Do not use the joint material in the joint directly adjacent to a plinth or other masonry. Use neutral filling sand instead, as otherwise there is a risk of efflorescence.

- Not suitable for bricks, tiles and porous natural stones

- Efflorescence can occur when the material is used under covered areas (carports, etc.). This can be removed with water or using a broom. Efflorescence under covered areas will eventually disappear as the excess of salts in the minerals diminishes.

- Use only on dry paving and in dry weather conditions.

| Step 1 | |

| The paving must be completely dry. |

| Step 2 | |

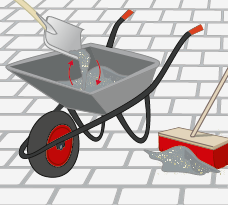

| Mix the filling material with a shovel in a mason tub or wheelbarrow so that the mineral additives are mixed well with the silica sand. Never mix the contents from more than two bags at one time. |

| Step 3 | |

| Sweep the filling material into the joints using a soft broom. Sweep diagonally across the joints until they are completely filled. |

| Step 4 | |

| Sweep the paving surface free from all granite dust using a soft broom. Otherwise the dust may leave a grayish residue which will disappear over time. You can also reduce the residue by scrubbing the paving after a rain shower. |

| Step 5 | |

| Compact the joint filling material by using a plate vibrator at least twice. Use a protective rubber mat to avoid damaging the paving. Check that the joint material is firmly compacted. The best way to do this is to use a spatula. You should only be able to press the spatula a few mm into the joint material. |

| Step 6 | |

| Top up the joints if necessary and sweep the coating free of excess material. NOTE! Avoid using the filling material in the joints adjoining the plinth as there may be a risk of expansion damage and efflorescence. Use neutral filling sand or laying sand in the joint adjoining the plinth. |

Vejledning og gode råd

Beregn, hvor meget fugemateriale, du skal bruge. Uanset om du skal fuge en ny belægning, eller blot skal fylde de eksisterende fuger op, er der hjælp at hente her på siden.

Her har vi samlet vores bedste råd til, hvordan du kan opnå de bedste resultater med vores effektive fugeprodukter. Hvilket fugemateriale skal jeg vælge?